By Jim Lewis, CEO Enhanced Retail Solutions LLC

At a recent meeting a financial planner asked me how to plan inventory when you can no longer rely on history. Just about everybody, and every system uses historic sales as the basis for predicting future demand. What else is there? But it’s a very valid point. There has always been a subset of items we had to manage without much knowledge. New items, items that have inconsistent inventory levels, changing retail factors and that whole pandemic thing. The world feels more uncontrollable than ever, so what are the best practices?

Reduce Planning Risk

While we may not get the accuracy we want, there are some things you can do to mitigate the risk of significantly over or under planning. Before we offer some ideas, the first thing you should do is rate the validity of history. On a scale of 0 to 5, 5 being the most consistent and reliable, put a number down for every sku. If you’re dealing with a lot of sku’s, this will help prioritize which items to focus on the most. Items with 0-2 will require the most attention. Here are some tips, not in any specific order.

- If a brick-and-mortar program, run the forecast at store level and roll it up. Doing so enables you to see what percent of the stores are in stock and get a better sense of how consistent selling is. Forecasting bottoms up will be more accurate than trying to do it on a chain-wide total.

- If history is inconsistent, try to calculate lost sales. We have several algorithms to do this, but even if you estimate it, add it to the basis of your forecast so you have a decent shot at having enough inventory to optimize sales.

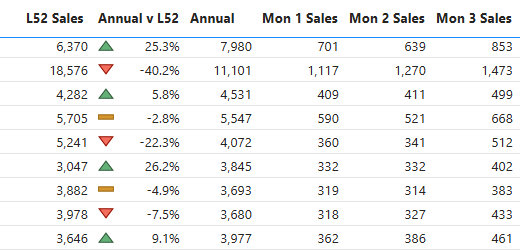

- Make some comparative inferences. Is business up or down the last 4 weeks compared to the same period last year? Are the average sales of the last 4 weeks close to what you were selling 12 weeks ago? Showing some trend information next to buy recommendations provides more data points for you to make an informed decision. For example, if the buy recommendation is more than what you sold all last year, is there really a trend to support that or is some component of the forecast incorrect (like the seasonality curve, etc.).

- Ensure promotions, calendar shifts and other events are factored into your seasonal profiles. Ask your retail partners for their total store or department traffic flow. Knowing when they expect more feet to be in the stores or fingers on the keyboards can provide general direction.

- Other 3rd party trend information can be helpful as well. Study the price elasticity of your product. Are sales affected when the price of gas goes up or down? In the home business, does your business rise and fall based on new home sales? There are many forecasts out there on those types of economic measures that you can integrate into your seasonality.

- Ensure your forecasting tool is flexible and easily customizable. The big-name systems are not. They are generally not very smart and are very costly to adapt. You want something where you can add more parameters and factors to use in the logic. This is why a lot of companies stay with spreadsheets to do their forecasting, but it really isn’t the most efficient or optimal way to do it.

Summary

There will always be items you just don’t have enough good information to make a good decision on. Then you must rely on your instincts. In those cases, prioritize sku’s you are willing to have more safety stock on. Flow less inventory, but more often. Whatever you do, make good notes. You want to be able to track whether the steps you took actually worked. Can AI help? Possibly. AI models will immediately look to the past to see what effects sales. A good predictive model will use a lot of the things we discussed here to make recommendations. For more information, contact us.

Comments are closed