Vendor Managed Inventory Service & Software

Vendor Managed Inventory

The ultimate way for retailer and supplier to share resources and collaborate.

ERS offers a mostly automated process for determining inventory needs by store by SKU. It takes advantage of shared resources from our Intelligentretail.net platform including sales curves, demand planning parameters, reporting and dashboards.

Our Vendor Managed Inventory Service

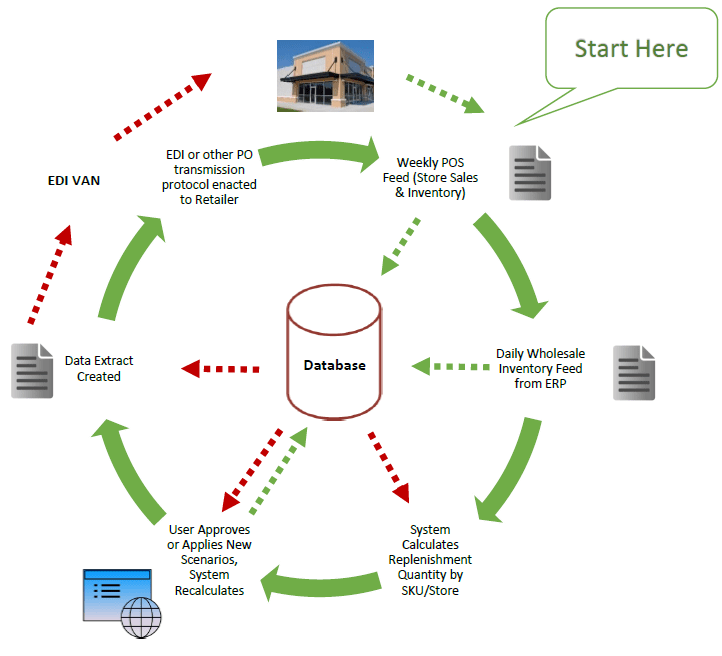

The process starts with a weekly POS data feed at store level from the retailer. Then, POS data is ingested along with the supplier’s wholesale inventory into our database and intelligence engine. The system then calculates multiple rates of sale by store, inventory requirements and recommends a replenishment quantity by SKU, by store. Once the user approves it, the system can recalculate using a different distribution scenario. Finally, the system recalculates and once approved, creates a data extract with purchase order details that can be transmitted back to the retailer.

The Benefits of Vendor Managed Inventory

Placing products in the right stores, minimizing costs and increasing profit is just the beginning. We assist users in tracking and gathering information relevant to their business.

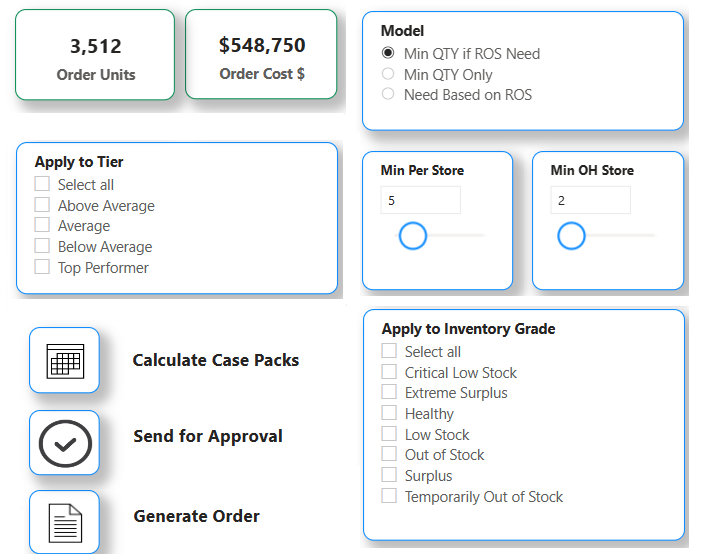

The process merges data points from various sources, makes calculations based on the user’s preferred replenishment scenario and displays the results in an interactive reporting tool. Then order quantities are reviewed- and approved or declined. Once approved a file in the user’s desired format (xml, text, etc.) is generated with the necessary information to transmit a live order. Additionally, the system can be customized to meet individual customer’s needs.

How Vendor Managed Inventory Works

This is the step by step process we follow. It can be customized based on each client’s needs.

Step 1

Seasonality curves are derived from historical sales, promotion plans and calendar shifts.

Step 2

De-seasonalized demand is calculated using multiple rates of sales over difference time periods. The system checks for stock-outs and makes adjustments for lost sales.

Step 3

The system then calculates actual needs based on the chosen rate of sale, the weeks of supply target and seasonality curve. It then compares the needs with the actual inventory and makes recommendations.

Step 4

Adjustments are then made based on constraints- like limited open to buy or lack of wholesale inventory. Users can select between multiple scenarios (feed high velocity stores first, give a little to every store, etc.).

Step 5

User reviews total inventory requirements, store level allocations and order cost. Once approved, a reverse PO is generated and sent to the retailer.