Inventory Planning

There are a million theories on how to improve inventory productivity. And a lot of companies think they must spend a million on a shiny big system to do it. But that isn’t necessarily true. Don’t get me wrong- you need something to automate and organize planning, especially if you have a high SKU count. What is often overlooked is formalizing a planning process. This is especially true for manufacturers. It’s often worth investing in some outside expertise to find out what you don’t know. Knowing what questions to ask, determining the most efficient way to do something or the best tool to accomplish it can save you a lot of time, money, and headaches down the road.

The Right Amount of Inventory

The goal is simple, yet hard to accomplish- having just enough inventory to satisfy demand. Excessive, stagnant inventory can kill a business while not enough inventory leaves money on the table. In many cases ERS is the planning team or complements a client’s inventory planning team. Here are 6 things we do that have demonstrated to improve inventory productivity.

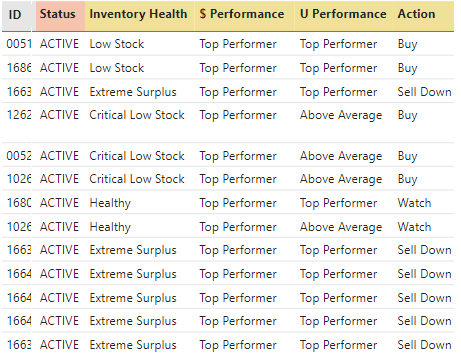

- Develop an Inventory Health Report: Create designations based on weeks of supply. For example, anything below 6 weeks is “Low Stock”, between 7 and 12 is “Healthy”, over 12 is “Surplus” and anything over 20 weeks is “Extreme Surplus”. Then use those designations on reports to quickly see how much of your inventory exists in each one. It also helps prioritize which SKU’s you need to focus on. Click here for an example.

- Implement a Discipline of a Planning: Formalize your planning process by outlining weekly, monthly, quarterly, ad-hoc, pre-season and post season tasks. Go beyond the weekly reporting routine and put SKU grading in place, check stock to sales ratios, frequency of purchases, etc. We have a great guide here.

- Focus on Opportunities and & Liabilities: Build action oriented dashboards and reports that each have a specific theme- like checking for changes in rate of sale or SKU’s with low or no sales. If you have a high SKU count, many times these opportunities or liabilities go unnoticed.

- Smarter Forecasting and Item Planning: Calculate lost sales and build them back into the basis of your forecast. Utilize ladder planning which more quickly catches a trend and shows you how much more opportunity, or how much trouble you may be in.

- Habitual SKU Rationalization: Constantly monitor performance and label the low hanging fruit. Score your previous buys- did your big bets work out? What is the optimal number of SKU’s that enable you to be profitable? We can help you get started with templates.

- Automate Vendor Managed Inventory: In today’s environment you can’t afford to miss a sale on anything- yet you don’t want a mountain of inventory. Collaborate and double the resources with more eyes and technology on every SKU-store combination.

Comments are closed