By Lennon Barrow, Business Analyst Intern at Enhanced Retail Solutions

Today’s forecast: cloudy and a chance of stockouts. When inventory is out of stock, it means disappointed customers and leaving money on the table. Stockouts translate to lost sales, or what the store could have sold if they had the inventory. It is a lose-lose-lose for the manufacturer, the retailer, and the customer. So, what can merchandise planners do to optimize inventory and prevent stockouts? To understand the end result, we will first look at the beginning.

It begins with data.

The process starts with how much POS sales and inventory data a retailer is willing to share. Suppliers can be a valuable resource for retailers, especially in helping them analyze the business. They can laser focus on their specific SKUs, maximizing sales while optimizing inventory. The more sophisticated retailers have learned that sharing data with their suppliers is mutually beneficial. Some retailers utilize VMI (Vendor Managed Inventory) in which the supplier manages the inventory including writing store orders. For a retailer with tens (or hundreds) of thousands of SKUs, a vendor with the right resources can better manage, and optimize, their inventory. To learn more about how VMI works, read our Vendor Managed Inventory Case Study.

Why is inventory optimization important?

Inventory optimization is a balancing act. Retailers must maintain the right level of inventory to meet customer demand while also considering the associated working capital. If retailers can find this balance, they can reduce operational costs, prevent overstocking, and reduce stockouts. This results in increased customer satisfaction and increased sales revenue.

What should merchandise planners be looking for?

When we take a look at the sales and inventory data for each store, there are two key indicators for inventory optimization. First, we will consider the stores with inventory and no sales. The second is stores that have sold out. Both scenarios require store level data over time to determine why either scenario is occurring.

Why is inventory not selling?

There are a number of factors to consider when stores have inventory but are not making sales. It may be the presentation of the inventory within the store, the preference of customers within the area, the price, or an inaccuracy in the stock count. For example, if the POS data suggests a store has three of an item, but the stock is not properly counted, those three items may be sitting in a back room or not exist at all. In order to achieve inventory optimization, it is essential to have correct inventory data.

How can we prevent stockouts?

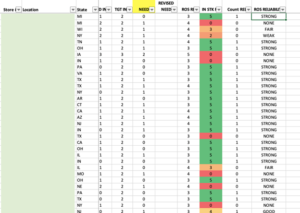

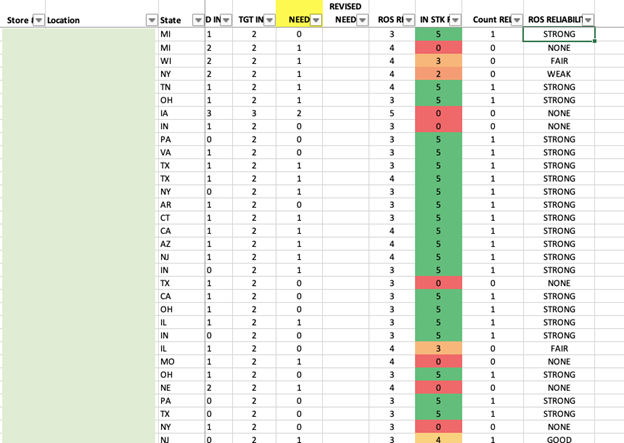

Similar to forecasting the weather, a retailer’s forecast gives us an idea of what to expect, but may not always perfectly predict events. If the forecast is based on history, when there are many stores experiencing stockouts, it indicates that the current rate of sale (ROS) data is not as reliable as desired. Here, we can see how ERS provides an in-stock ranking and ROS reliability ranking, based on sales data. Five represents the best, or highest reliability while a 0 represents none.

Rating the reliability of rate of sale over time helps improve forecasting accuracy.

Next, we can filter out the stores with a higher in-stock rating and focus on those with a ranking of 0, 1, or 2. These locations are experiencing the most stockouts and have weaker ROS reliability. We can calculate a revised inventory need using a simple calculation to factor in the lost sales.

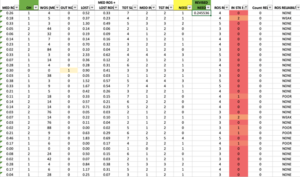

The median ROS and lost ROS was calculated over a period of 8 weeks. Thus, (MED ROS + LOST ROS/8) X Coverage Period.

Calculating inventory needs by adjusting the rate of sale.

Then, compare this to OH.

If OH is greater, then the revised need is 0.

If OH is less, then the revised name is the difference between the calculated need and OH.

Example: The calculated need is 0.25, but there is already 1 on hand. Thus, the revised need is 0.

In addition, merchandise planners can see which locations keep selling out and prioritize these high velocity stores. Tomorrow’s forecast: sunny skies and happy customers!

Comments are closed