By Jim Lewis, CEO Enhanced Retail Solutions LLC

I recently had the honor of lecturing at my alma mater, the University of Florida. We discussed the basics of retail analytics, the tools and roles of retail and wholesale inventory planners. We talked about how merchandise decisions are made to hopefully make magic on the sales floor. But the magic doesn’t always happen.

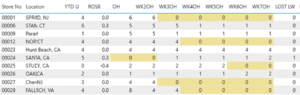

A student asked what causes a store to have empty shelves. That’s a whole lecture within itself. We talked about some of the reasons- what can be controlled and what can’t. They know what they read- that the pandemic caused havoc on the supply chain. While that is real, there are many other causes, especially now that the supply chain is easing. We focused on studying the mechanics of how out of stocks result in lost sales. One of the reports I showed the inventory of an item by store by week, highlighting when it was out of stock. Students quickly did the math to figure out how much money was being left on the table.

Track inventory by sku by week by store to find outs and lost opportunity.

Predicting Out of Stocks

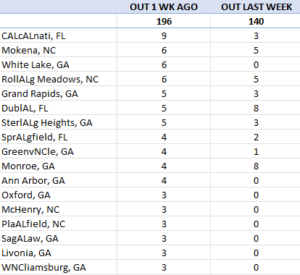

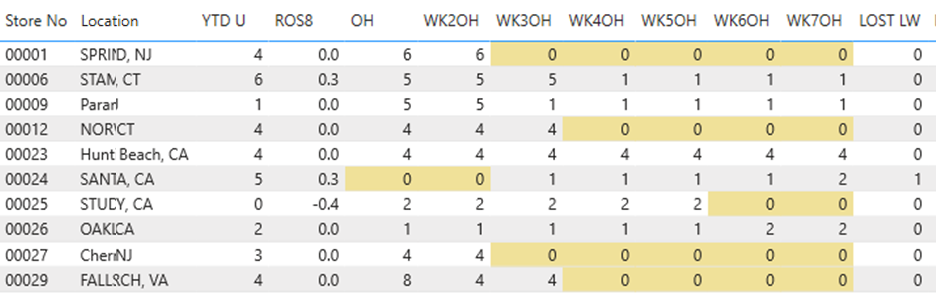

While there are some retailers whose philosophy is that they’d rather be out of stock than mark down an item, the vast majority don’t want to be out of stock. Preventing stock outs requires a lot of moving parts to sync harmoniously. There must be a consistent flow of inventory coming from the wholesale side with peaks and lulls taken into consideration. The allocation process depends very much on the sophistication of the retailer. Some auto replenishment systems simply stick to a minimum quantity, some add rate of sale to that, but most aren’t smart enough to prioritize stores and items that are out the most. And many don’t add back lost sales, which means the entire basis for the forecast doesn’t reflect the true potential. Then there is the sheer volume of sku’s- millions of sku-store combinations to manage.

Keep track of the stores or items that are consistently out of stock.

VMI

The best method for staying in stock is VMI (Vendor Managed Inventory) where the retailer employ’s their supplier’s resources to forecast and ensure stores stay in stock. It basically means those sku’s will have more focus on them than non-vendor managed items. This focus enables the supplier laser focus on stores and sku’s that are most likely to go out of stock, and beef them up.

Scenarios

Even with the best of intentions, there may not be enough inventory or open to buy to allocate in the most efficient manner. That’s why documenting scenarios is important. If you only have so many resources- which stores or items gets fed first? What gets prioritized? Or does every store get a smaller amount? These may change depending on the situation, but we recommend developing a “play book” so there’s a plan in place.

Data Science

It really isn’t brain science. We have an abundance of reports and systems that constantly study which items and stores are sold out- so that inventory can be prioritized to fix the problem. Based on a combination of data points- wholesale inventory flow, historic store and item stock outs, seasonality, promotions, etc., we use a few simple algorithms to do the work. It does require powerful computing power to sift through millions or billions of records of data, so it is not for the faint at heart.

I always enjoy talking to students. At its heart, ERS was founded on education- teaching manufacturers to think and act like retailers. It has evolved into much more over the last 20 years, but teaching remains a core focus of our business.

For more information, contact us.

Comments are closed