The Shared Inventory Conundrum

By Jim Lewis, CEO Enhanced Retail Solutions LLC

For many years we have worked with clients and brands that sell the same SKUs to multiple retail outlets. They share a common inventory which can make anticipating future needs a challenge. Some retailers provide a forecast, but most expect suppliers to maintain enough inventory to keep them in business. And now with many brands going direct to consumer via their own websites, managing shared inventory is even more of a challenge.

Standardizing Data

The key to getting a handle on shared inventory is to build a bottoms-up forecast by SKU by retail account. Not just what is expected to sell, but how much each retailer will need to buy to maintain their model inventory. To do that you’ll need POS data for each account, a seasonality profile, and any known planned promotions. Those last 2 elements can be different depending on the retailer’s philosophy. If sales are not available, you can use past shipments. Using a demand planning system or your internal process, derive monthly inventory requirements by retail account.

Reservations

Most suppliers produce an inventory report that only provides total units available and doesn’t break it down by retail account. I have yet to see an off the shelf inventory system that handles the allocation or reservations by retailer pain point. Still, it needs to be done. A ledger with available to sell and work in process by retail account needs to be kept. Basically, a reservation ledger. Reservations by SKU by retailer can be accomplished in Excel, using a tab with all the data and a pivot table to provide the details and total. If I lost you there, contact us and we can help you.

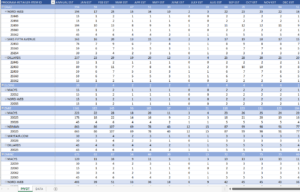

Summarizing estimated sales or inventory requirements by Retailer, by SKU by Month

Status

Another key element to managing shared inventory is communication. If your organization has multiple salespersons, they may each be trying to sell the same inventory. They need to know what the story is with each item. You can do that with a good status system. The status can be reflective of the attitude towards the inventory. For example, “S” could mean strict- reserved by account. “F” could mean flexible, check reservation first, or “O” for open, denoting there are no reservations, and all can be sold. The status can be maintained in the inventory ledger mentioned above.

Completing the Ledger

The ledger can be completed by adding in the current ATS (available to sell) and factory orders aligned by month. Then you can do the math to project inventory positions at the end of each month. Every organization is different, but the concept is to break everything down at the lowest level. Exception reports can be derived from the ledger- inventory that hasn’t been taken when expected or projected under or over situations.

Comments are closed