By Jim Lewis, CEO Enhanced Retail Solutions LLC

Smart retailers will take inventory from anywhere within their sphere to make a sale. If an online customer wants an item and it must be pulled from a store, so be it. I get it, anything to make the sale. Yet it does inject another level of complexity into inventory planning. Even with the abundance of data that’s available today to retail and wholesale planners, every week we can pick almost any program at any retailer and find a good number of stores out of stock. And expensive, sophisticated allocation tools may not be able to predict if an online customer will want to pick up or have shipped their package from a specific store.

Studying the Business

Retailers, and wholesalers to some degree need a living, breathing inventory model that allows for the movement of inventory through the supply chain. The retailers that can act the quickest and be nimble will win the game.

We’ve always believed the key to increasing sales and profit is following the inventory. Constantly quantifying lost sales and pinpointing stores that have an opportunity to better balance their inventory is the goal. Suppliers can help their retail partners greatly in this quest. A buyer and their respective planner only have so many resources (tools, time, etc.) to study the business. But if each supplier takes their piece of the pie and optimizes it, it’s a win-win for both.

Getting POS Data

The retailer must provide the POS data at the appropriate level for it to work. They need to share sales and inventory at store level, warehouse, or eCommerce DC’s. Suppliers can then compute rates of sale by location and determine how long inventory at each location will last. For out-of-stock stores or unfulfilled online orders, lost sales should be calculated and built back into the inventory model. This also helps the supplier plan future production because the forecast will be far more accurate.

When you’re dealing with thousands, hundreds of thousands, or millions of sku-store combinations it can get tricky. You need a smart system that can prioritize the biggest problems or opportunities. That’s where AI can be very helpful.

Inventory Planning Tools

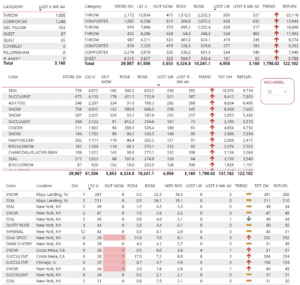

This interactive dashboard not only highlights the problems, but it also provides a recommended allocation by store to balance inventory. If a retailer can move products between stores, it will recommend the most efficient transfers. It also keeps track of how frequently a particular store is out of stock, and which items might contribute to the problem. It provides a roadmap for reducing lost sales and ensure every unit of inventory has the greatest chance of being sold.

Track inventory by location, stock outs and lost sales

Inventory tracking by store and lost sales calculator

I know this seems obvious, but many retailers and suppliers just don’t do it and they are missing out on a huge opportunity. Sometimes it comes down to philosophy. A Target buyer told me many years ago they would rather lose a sale than take a markdown. But with today’s tools and a more practical application of AI, there’s no reason to do that. It’s easier than ever to predict which stores will sell out and when. The key is ensuring the pipeline is properly filled to meet the demand.

Comments are closed