By Jim Lewis, CEO Enhanced Retail Solutions LLC

Tis the season for VMI. We are seeing an increase in inquiries from suppliers asking for help to understand how to successfully manage these programs. It requires a combination of skill sets, technology and expertise.

For those who are not familiar, the name implies exactly what it is: Vendor Managed Inventory. The supplier (vendor) manages the allocation and inventory support by SKU by Store for the retailer. That means the supplier writes their own orders. The retailer may provide blanket approval or require oversight on an agreed upon cadence. There are great benefits for both the supplier and retailer.

Benefits of Vendor Managed Inventory Programs

The retailer’s risk is reduced because they don’t have to own as much inventory. They also don’t have to allocate resources to managing those sku’s and stores. They generally see better in-stocks and increased sales and profit. With the supplier looking after their “piece of the pie” they can really maximize it.

Suppliers like it because they gain some control over the business. They can optimize allocation by analyzing every SKU-store combination and balancing inventory. That increases sales and profit. It is a lot of work but worth it. One client put it like this: it’s like building a moat around the business- it blocks out competitors.

Successful VMI programs require careful stewardship on the part of the supplier. Large CPG companies have sophisticated software and teams of people to run the programs. Smaller companies can achieve the same results by getting help from companies like ERS. Suppliers need:

- Data: Store level point of sale (POS) data that includes sales, on hand and on order. For most retailers this is the EDI 852 document. It can be automatically transmitted. The data may also be downloadable from a retailer’s vendor portal. The supplier’s wholesale inventory from the ERP system is also needed.

- Database: The data needs to be collected (generally weekly) and history built up. Queries can then be derived to find trends and aid in calculations.

- Inventory Model: The retailer generally provides guidance on how much inventory they are willing to carry. Minimum, maximum or weeks of supply models by store.

- Logic: Rate of sale calculations, business rules and allocation methodology. For example, how to adapt recommended orders to fit into open to buy limitations.

- Software to automate all the processes and create reverse PO’s. A user-friendly interface that provides visibility to orders and approvals, etc.

ERS offers a mostly automated process for determining inventory needs by SKU by store. It takes advantage of shared resources from our intelligentretail.net platform includes seasonality sales curves, demand planning parameters, reporting and dashboards.

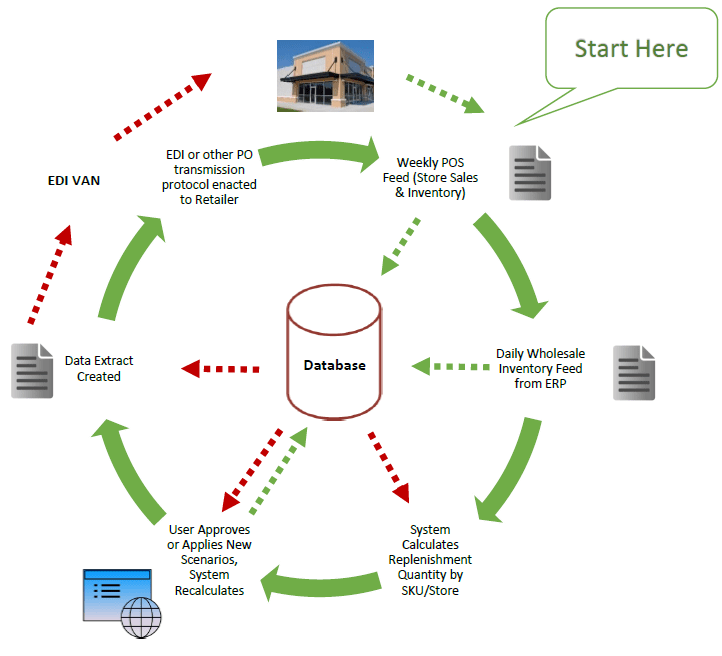

The VMI Cycle

The VMI Cycle

The process starts with a weekly POS data feed at store level from the retailer. That POS data gets ingested along with the supplier’s wholesale inventory into our database and intelligence engine. The system then calculates multiple rates of sale by store, inventory requirements and recommends a replenishment quantity by SKU by store. The user approves it or asks the system to recalculate using a different distribution scenario. The system recalculates and once approved, creates a data extract with purchase order details that can transmitted back to the retailer.

For suppliers interested in taking on VMI programs, visit the VMI page on the ERS website for more information.

Comments are closed